Stabilized Starling Resistor

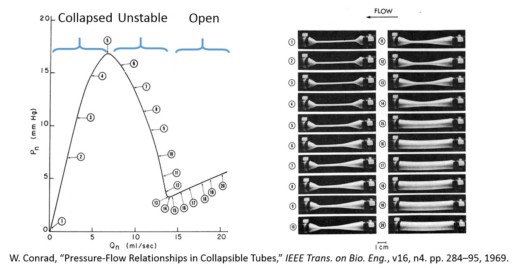

Problem: Early tests confirmed that a Starling Resistor (collapsing tube) would throttle the flow as required, however, they are famous for oscillating (like a Whoopie Cushion). To increase the life expectancy of my product I needed to remove the oscillations.

Analysis: The literature on Starling Resistors focused on how to model the instability, not how to prevent it. Instead of immediately spending 6-12 months working on the modeling problem, I observed the process in the lab and noted that the instability was multi-modal and sensitive to boundary conditions.

Tested Strategies: At the suggestion of my advisor, I tried to disturb the buckling process in order to stabilize the system. I smoothed the boundary conditions and removed several modes of collapsing by pre-buckling the membrane, and by inserting a rigid support inside the membrane.

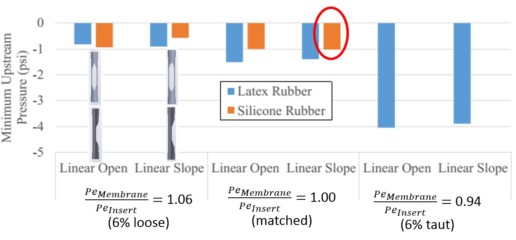

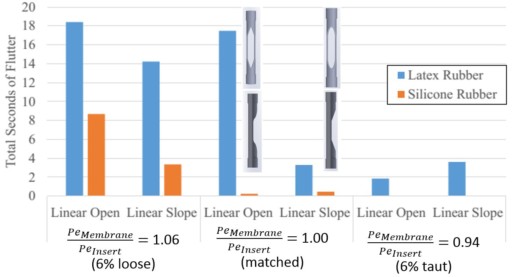

Tested Concepts: The rigid insert worked! But the design needed optimization; I hypothesized the there were three critical parameters: the shape of the opening, the ratio of the inner perimeter of the soft tube to the perimeter of the rigid insert, and the material of the soft tube. Using a full factorial design of experiments, I tested two materials, two opening types, and three perimeter ratios.

Optimized Design: Experimentation showed that the perimeter ratio was critical. Loose membranes were better at resisting negative pressure, but fluttered more. The optimized design balanced this trade-off by making the inner perimeter of the membrane equal to the outer perimeter of the insert. It also used silicone rubber which is less prone to fluttering.

Remaining Issues: Before this design could be implemented in the field, it needed to be made more durable and tamper proof.

Other Design Stages: The overview of this design is here. But more detailed entries about other design stages are linked to below:

- Problem Analysis & Initial Strategy Selection – choosing a pressure sustaining valve

- Concept Generation and Selection – choosing a Starting resistor

- Concept Refinement – inventing a stabilized Starling resistor

- Tamper Proofing – separating the user from the sensitive parts

- Increasing Durability – moving away from plastic parts

- Decreasing Costs – reducing the part count and complexity

- Field Testing – verifying performance in Delhi