Reduced Cost

Problem: A 1kg metal valve would never become cheap enough to be installed at every home in India. The mass and complexity of the design needed to be reduced.

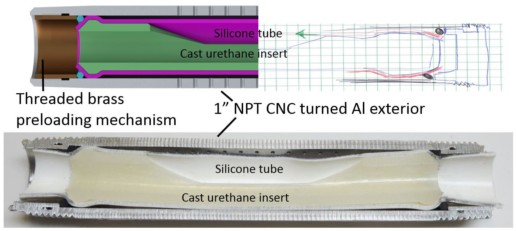

Analysis: Having one reinforcing layer and one outer shell was a design hold-over from the reference pressure chamber and was no longer necessary; the two metal layers could be combined into one, which would reduce the outer diameter. Further, changing from steel to aluminum would further reduce the device’s mass.

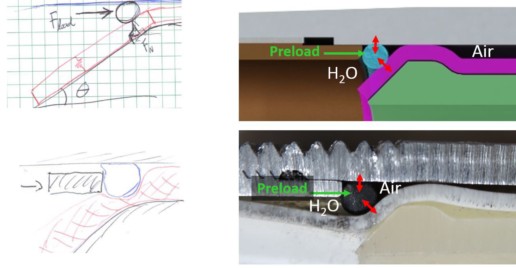

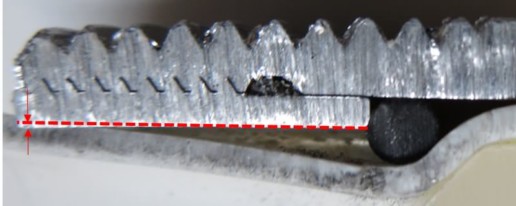

Solution: The membrane was sealed to the outside housing by using an O-ring in a crush configuration. In order to test the required level of compression for an O-ring seated on a softer surface, a threaded preloading mechanism was used. This new design cut the volume of metal required by 25% and the mass by 66%. The outer diameter was reduced from 1.25″ to 1″ NPT pipe.

Remaining Issues: Tapered pipe threads deform plastically under normal conditions, this prevented the re-adjustment of the preloading mechanism. Removing it entirely would further simplify the design. Additionally, clients would always like lower costs. Accordingly we are testing new versions of an exclusively plastic valve. Finally, in production, no aluminum should be in a drinking water pipe, so the materials used in this design will need to be adjusted.

Other Design Stages: The overview of this design is here. But more detailed entries about other design stages are linked to below:

- Problem Analysis & Initial Strategy Selection – choosing a pressure sustaining valve

- Concept Generation and Selection – choosing a Starting resistor

- Concept Refinement – inventing a stabilized Starling resistor

- Tamper Proofing – separating the user from the sensitive parts

- Increasing Durability – moving away from plastic parts

- Decreasing Costs – reducing the part count and complexity

- Field Testing – verifying performance in Delhi