Concept Generation

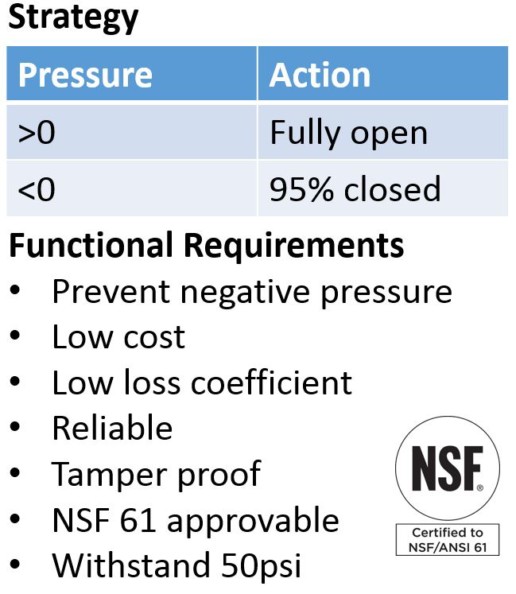

Problem: Find an method of implementing the strategy that meets the functional requirements

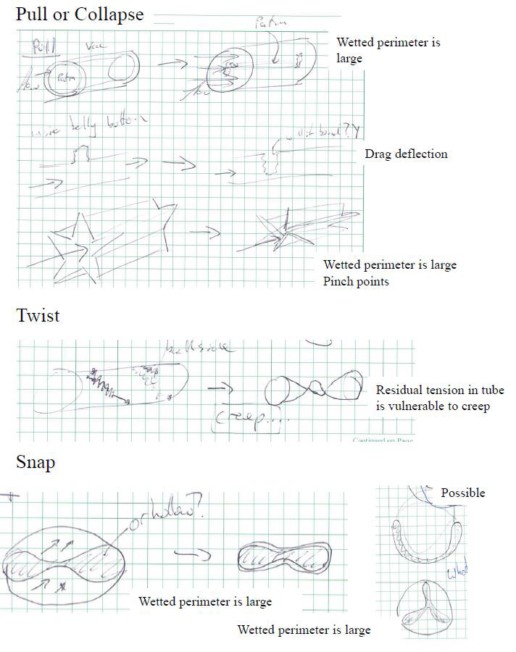

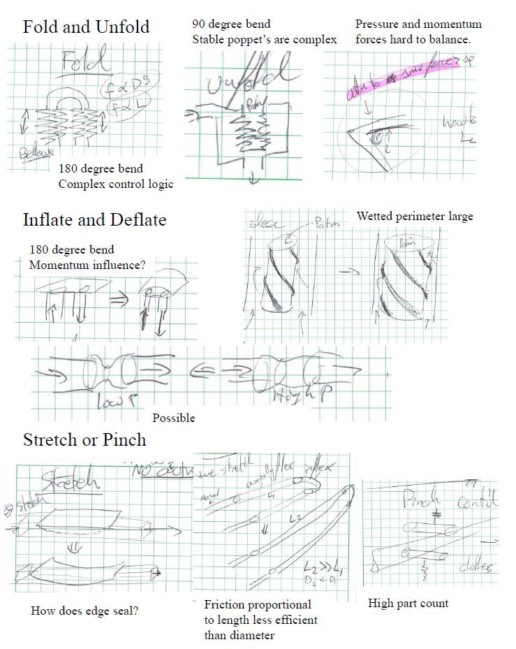

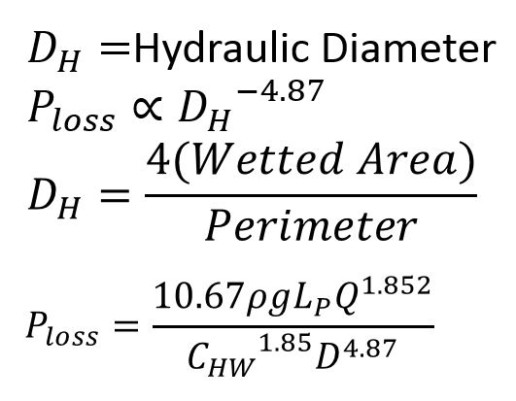

Analysis: In order to meet the functional requirements, I needed a strategy that minimized pressure losses, minimized part count and would be easy to manufacture.

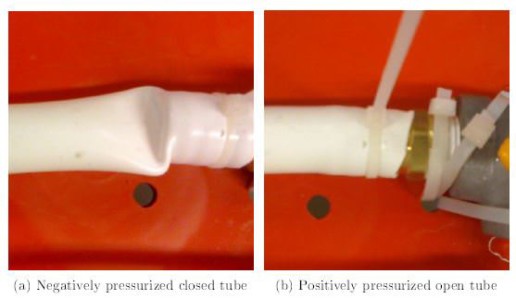

Selection: Using scaling laws from the Hazen-Williams equation, most elaborate designs were eliminated and the collapsing tube concept was selected and tested in a bench-level prototype:

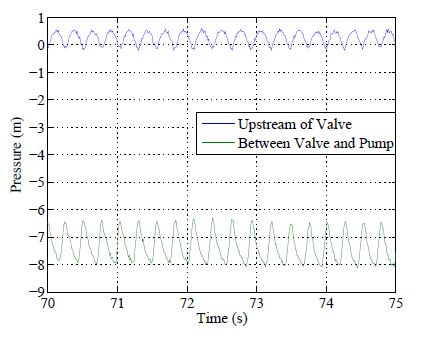

Remaining Issues: While the bench-level prototype met the key functional requirement of enforcing atmospheric pressure upstream of it, its oscillations needed to be addressed. Collapsing tubes used to restrict flow are famously unstable and known as Starling Resistors.

Other Design Stages: The overview of this design is here, and more detailed entries about other design stages are linked to below:

- Problem Analysis & Initial Strategy Selection – choosing a pressure sustaining valve

- Concept Generation and Selection – choosing a Starting resistor

- Concept Refinement – inventing a stabilized Starling resistor

- Tamper Proofing – separating the user from the sensitive parts

- Increasing Durability – moving away from plastic parts

- Decreasing Costs – reducing the part count and complexity

- Field Testing – verifying performance in Delhi