Reinforced and Tamper Proof Valve

Problem: The stabilized starting resistor had two reasons it was not yet ready for deployment as a proof of concept prototype: 1) the collapsing membrane would burst if inflated to system pressure (max 100 psi), and 2) the device was not tamper proof.

1) Analysis: I needed a design that would collapse easily but resist expansion. Buckling is one traditional solution to this problem – slender beams are strong in tension but weak in compression. The other traditional solution is to separate functionality – a flexible material expands into a rigid material.

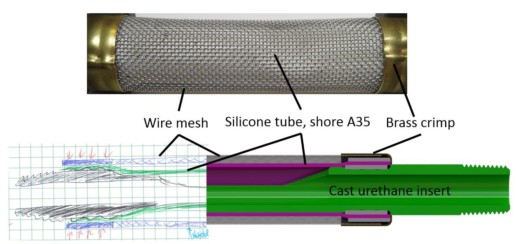

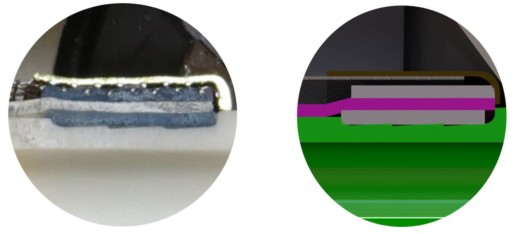

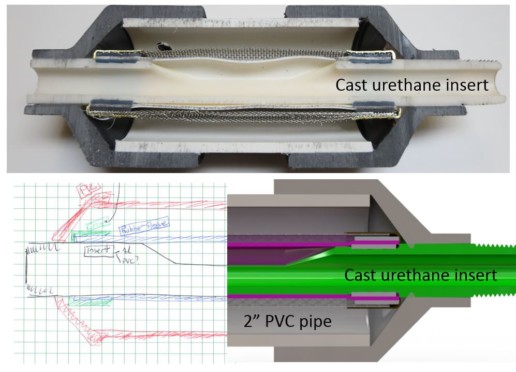

1) Solution: Separating functions led to a cheaper prototype with fewer custom components. The critical module was wrapped in a wire mesh to resist expansion. The mesh allowed air to flow through it so that the membrane would still have atmospheric pressure on one side of it. The interface between the soft membrane and rigid components was eased with a strain-transition material.

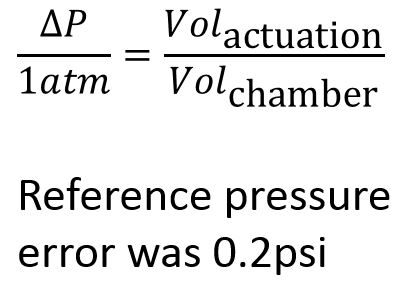

2) Analysis: The designed starling resistor needed to compare the internal fluid pressure to the external atmospheric pressure. Unfortunately, using a simple pressure port could create an opportunity for tampering. I avoided this problem by using a sealed reference pressure chamber. However as the membrane deflected the volume of reference pressure chamber changed, thereby changing the pressure.

2) Solution: The volume of the reference pressure chamber was sized to keep the volume-induced pressure error within 0.2 psi. Erroneously, thermal effects were not considered at this stage of the design.

Remaining Issues: Early versions of the valve used cast urethane threads, which frequently failed. Further, the strategy of using a reference pressure chamber meant that if an internal seal leaked (even ever so slowly), the valve’s set point pressure would drift and the valve would fail shut. Both of these problems were addressed in the next design iteration, which focused on increased durability.

Other Design Stages: The overview of this design is here. But more detailed entries about other design stages are linked to below:

- Problem Analysis & Initial Strategy Selection – choosing a pressure sustaining valve

- Concept Generation and Selection – choosing a Starting resistor

- Concept Refinement – inventing a stabilized Starling resistor

- Tamper Proofing – separating the user from the sensitive parts

- Increasing Durability – moving away from plastic parts

- Decreasing Costs – reducing the part count and complexity

- Field Testing – verifying performance in Delhi